Fastest TIG Welding Process Available

Highest Deposition Rates for Any Tig Process Available on the Market

Highest Deposition Rates for Any Tig Process Available on the Market

Fastest semi-automatic manual GTAW

Fastest semi-automatic manual GTAW

process available

Simple to Learn,

Simple to Learn,

Simple to Use,

Simple to Teach

One single process from root to cap

One single process from root to cap

The Evolution of TIG…TIP TIG

The TIP TIG arc welding process is a unique hot wire TIG welding process for manual welding that uses our patented wire feed technology. Our system’s benefits will provide the highest quality, highest deposition rates with the lowest possible heat input. TIP TIG is consistently delivering the most excellent metallurgical results on any alloys. It has also proven to provide the lowest possible hexavalent chrome weld fume emissions, measured as undetectable.

Unlike nearly all other hot wire TIG welding processes, it can be operated manually in all positions and with our patented automation systems. A widely recognized benefit we deliver is the reduction in labor costs associated with costly rework and training.

Simply put, it’s just simple to use, to teach, and to learn!

Top Benefits of Tip Tig Welding Systems

-

Up to 300% faster welding speeds compared to TIG welding

-

Up to 400% improvement in deposition rate

-

Dilution reduced by up to 80%

-

Dynamic wire feeding for a controllable weld pool even with positional welding

-

The wire feeding is superimposed in parallel using a backward/forward movement

-

Higher welding speed and easy handling

-

Perfect weld appearance, no weld spatters

Tip Tig Cap

Tip Tig Root

Tip Tig Fill

Tip Tig 5G Weld Test

Tip Tig in Action

Compare Tip Tig to Other Welding Processes

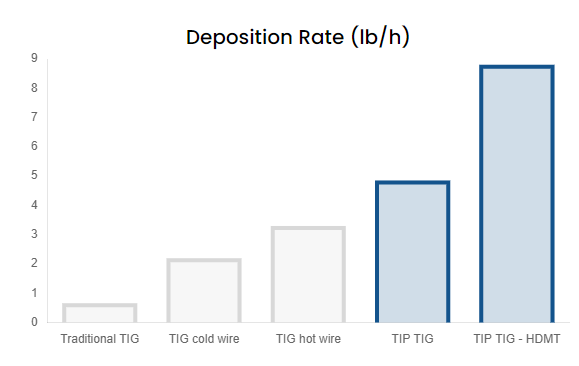

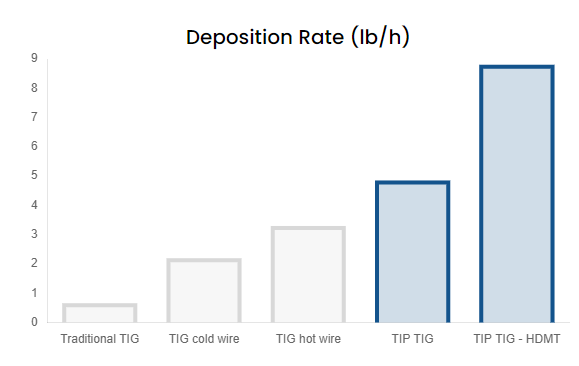

Higher Deposition Rates

Deposition rate on a real stainless steel welding application comparing conventional TIG, TIG cold wire, TIG hot wire, TIP TIG and TIP TIG – HDMT on a pipe application.

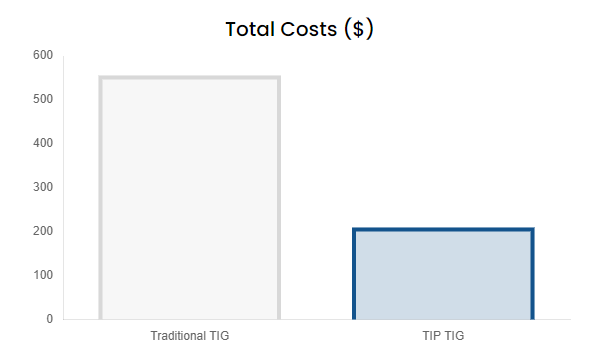

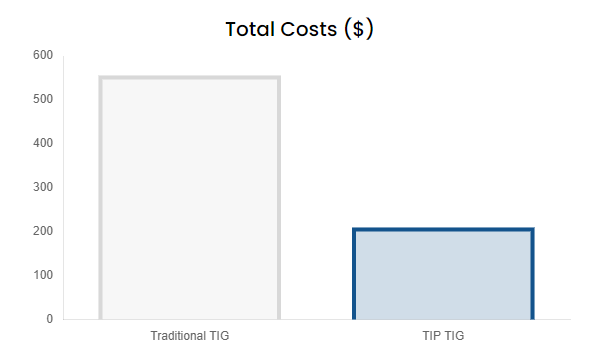

Lower Welding Costs

Savings calculated on a real stainless steel welding application comparing conventional TIG and TIP TIG on a pipe application

Learn More About Tip Tig

Standard welding machines can be connected to the TIP TIG process. Our patented wire feed system introduces a vibration to the filler wire and as well as a pre heat to the filler material prior to entering the weld puddle. The vibratory effect comes from a mechanically applied agitation using a 4-roll wire drive unit. The hot wire current is created by a secondary power source within the TIP TIG wire feeder. The TIP TIG welding process is most beneficial on alloys like Carbon Steel, Stainless Steel, Duplex and Super Duplex Stainless Steels, Inconel, Stellite, Titanium, Hastelloy, Copper Nickel, Nickel Chrome Alloys and for Aluminum welding. The core application of the TIP TIG process is to attain higher travel speeds and increasing productivity of TIG welds using GTAW

Learn About TIP TIG Welding Systems

Featured TIP TIG Welding Systems Product Applications

Industry Applications