Hastelloy 276 Welding Applications

TIP TIG and a Hastelloy 276 31 – Shaft to a Flange Weld.

The weld on this side of the flange face has to fill in the flange groove, (future flange wear area).

The other side of the flange is a 6 mm fillet that will join the shaft to the flange.

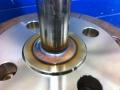

TIP TIG part shown below, please note “untouched single pass Hastelloy 276 groove flange fill pass. The TIP TIG weld time was under 30 secs. Then we turn the flange over to provide a fillet to weld to join the rear side shaft to the flange.

This side of the flange required a Hastelloy 276 shaft to flange fillet weld.

Note. The silver color and small HAZ from this untouched, single pass, TIP TIG fillet.

The TIP TIG process makes these welds four times faster than regular TiG.

The TIP TIG weld cycle time was approx. 20 sec. for this weld.

The TIP TIG process always puts in much less weld heat than pulsed MIG, and approx. 30% of the weld heat of the regular TiG process. With TIP TIG, less welder skills are required and the combined weld cost labor – consumable costs were reduced by approximately 80%.

Note regular TiG would also use twice as many weld passes. So with any alloy weld application, you know the benefits that will be attained from a process that consistently deliver the highest possible weld quality, the lowest possible weld heat, the least possible weld cleaning and lowest weld fumes.

Every alloy part benefits from the lowest possible weld distortion and the best possible weld metallurgical properties…It’s called TIP TIG.

The pictures below were done on our Automation system.